Introduction to Electric Blanket Fire Hazards

Electric blankets are specially designed bedding products equipped with thin, insulated wires to generate heat when connected to an electric power source. These blankets consist of two main components: the fabric layer, which is typically made of soft, durable materials such as polyester or fleece, and the heating element, which is embedded within the blanket. The operation of electric blankets is straightforward; users can adjust the heat settings according to their personal comfort preferences, allowing for customized warmth throughout the night.

The primary benefit of electric blankets is their ability to provide warmth. They are particularly advantageous during cold seasons, offering an efficient and consistent heat source that can easily help alleviate the discomfort of freezing temperatures. Many individuals rely on electric blankets for improved sleep quality, as the gentle warmth creates a cozy environment conducive to relaxation and rest. In addition to enhancing comfort, electric blankets can help promote therapeutic benefits, such as alleviating muscle pain, easing joint stiffness, and providing relief from ailments like arthritis. These advantages make them an appealing choice for those seeking extra comfort and health benefits from their sleep environment.

Moreover, electric blankets have gained significant popularity in both residential and commercial settings. In homes, they are commonly utilized during colder months to maintain a cozy atmosphere. In commercial environments, such as hospitals or wellness centers, electric blankets can serve as a valuable tool to support patient comfort and recuperation. Their flexibility and variety of functionalities have led to increased adoption. However, as their usage continues to grow, it is crucial to evaluate their safety standards and certifications to mitigate any associated fire hazards.

The Fire Hazards Associated with Electric Blankets

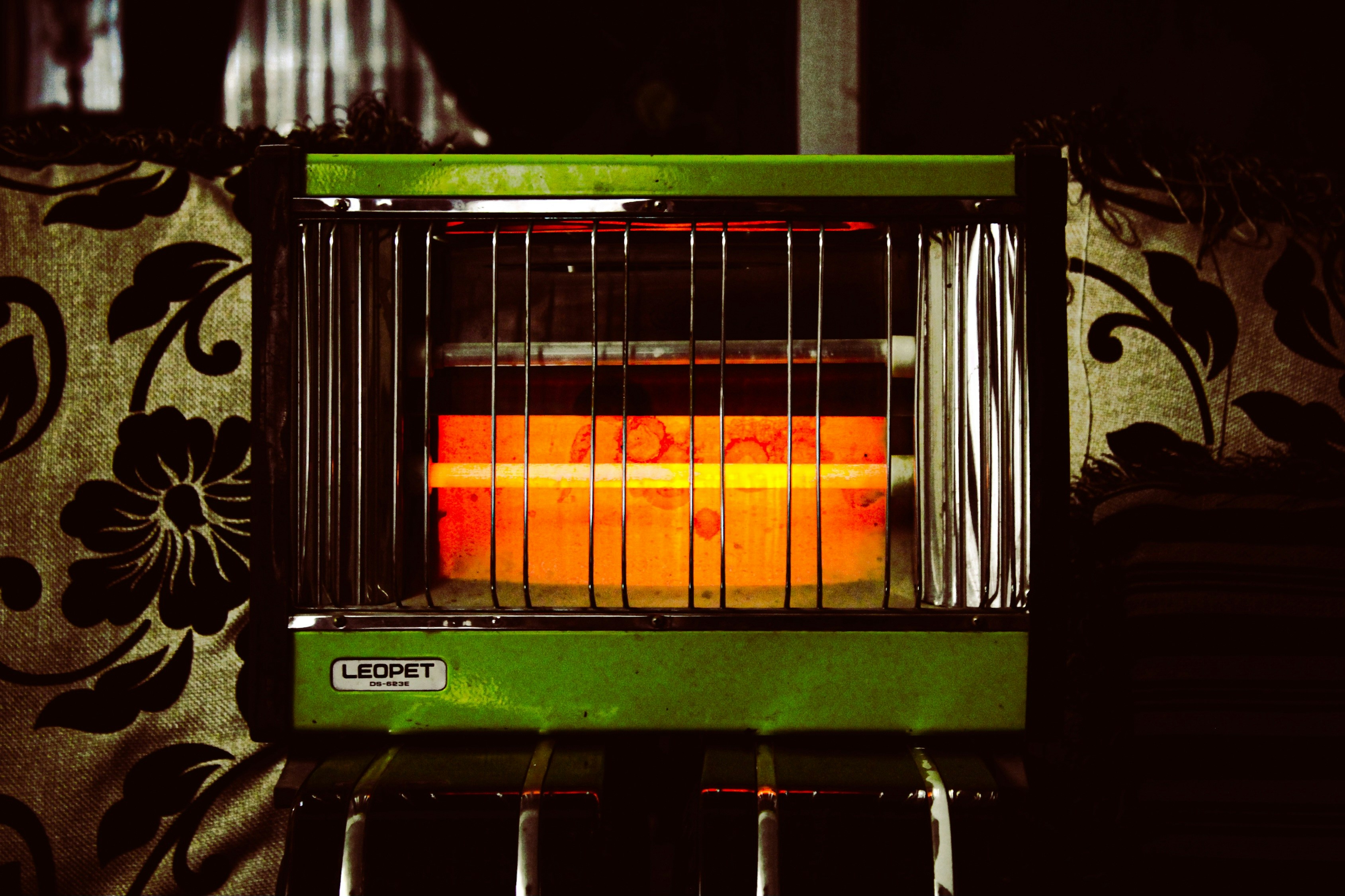

Electric blankets, while popular for their comfort and warmth, present several fire hazards that must be acknowledged. One primary concern is related to faulty wiring. Over time, the wiring within electric blankets can become frayed or damaged, increasing the risk of sparking and potential ignition. Manufacturers recommend regular inspections of electric blankets, as the wear and tear from everyday use can often go unnoticed until it leads to a hazardous situation.

Improper use is another significant factor contributing to fire hazards associated with electric blankets. Many users may inadvertently misuse these products by layering additional bedding on top of the blanket. This practice can result in overheating since electric blankets are designed to operate within a specific range of temperatures. It is crucial to follow the manufacturer’s guidelines regarding usage to minimize these risks. Additionally, leaving electric blankets on for prolonged periods, especially when unattended, has led to numerous fire incidents, underscoring the importance of monitoring their operation.

Lack of maintenance also plays a considerable role in the safety of electric blankets. Dust and debris can accumulate on these devices, insulating them and hindering proper heat dissipation. As temperatures rise, the risk of overheating increases, which can lead to fire. It is advisable to clean electric blankets according to the manufacturer’s instructions and to store them properly when not in use. Real-life statistics emphasize these hazards, with data from fire departments indicating that electric blankets are involved in thousands of fire incidents each year. Developing an awareness of these fire hazards is essential for ensuring safety and preventing accidents.

Commercial Use vs. Domestic Use: Key Differences

The use of electric blankets varies significantly between commercial and domestic settings. In residential environments, electric blankets are typically utilized for personal comfort during cold weather. These products are designed to provide warmth and can be operated under normal household conditions, where the usage is relatively controlled and limited. However, in commercial settings, electric blankets are subjected to a more rigorous usage pattern and must meet stricter standards due to their higher intensity of use.

Commercial environments, such as hotels, spas, and healthcare facilities, often require electric blankets to be in continuous operation to meet the demands of multiple users. This increased frequency of use results in a greater exposure to wear and tear, which can compromise the integrity of the blanket over time. Moreover, commercial users may require heavy-duty electric blankets that can sustain prolonged use without overheating or malfunctioning, highlighting a fundamental difference in performance expectations between commercial and residential products.

Additionally, the fire safety risks associated with commercial use of electric blankets cannot be understated. In environments where many individuals may come into contact with these devices, the potential for accidents, such as overheating or electrical failures, significantly escalates. Therefore, commercial electric blankets must adhere to higher safety certifications and regulatory standards. These standards are aimed at ensuring enhanced durability and robustness, as well as minimizing the fire hazards posed by faulty or improperly maintained blankets.

Ultimately, while domestic electric blankets are suitable for personal comfort, commercial users require specially designed heavy-duty options that prioritize safety, longevity, and compliance with established fire safety regulations. This distinction between the two categories underscores the unique challenges faced by commercial operators in managing electric blanket usage and ensuring user safety.

Standards and Regulations Governing Electric Blankets

The safe use of electric blankets, particularly within commercial settings, is governed by a comprehensive framework of standards and regulations aimed at ensuring consumer safety. Central to these guidelines are organizations such as Underwriters Laboratories (UL) and the American National Standards Institute (ANSI), which set forth rigorous criteria for the design, manufacturing, and testing of these products. Compliance with these standards is essential in mitigating fire hazards associated with electric blankets, particularly in environments where they are utilized on a larger scale.

One of the primary standards is UL 858, which pertains specifically to electric blankets and defines safety requirements aimed at minimizing the risk of fire and electrical shock. This standard outlines testing procedures that electric blankets must undergo to ensure they can safely operate under various conditions without failure. The inclusion of features such as automatic shutoff timers and temperature regulation mechanisms are critical components evaluated in this testing process.

Another crucial standard that influences the commercial use of electric blankets is ANSI/AAMI HE75, which focuses on the safety and effectiveness of heating devices in healthcare settings. This standard emphasizes the need for these blankets to provide consistent heating while reducing potential hazards, such as overheating, that may lead to burns or electrical malfunctions.

To maintain the highest safety standards, electric blanket manufacturers are encouraged to adhere to these guidelines rigorously. The certification attained from organizations like UL assigns credibility to the product, assuring consumers and businesses that they are investing in a reliable heating solution. Additionally, ongoing inspections and tests are mandated to ensure compliance with changes in regulatory standards. Thus, understanding these standards is critical for anyone involved in the commercial utilization of electric blankets, as they serve as the foundation for safety and effectiveness in their operation.

Certifications That Ensure Safety and Quality

Electric blankets are widely utilized for their convenience and comfort, but ensuring their safety and quality is paramount given the potential fire hazards associated with their use. Various certifications are established to ensure that electric blankets meet specific safety standards, thus protecting consumers and businesses alike. One of the primary certifications for electric blankets is the Underwriters Laboratories (UL) certification. UL is a trusted entity that evaluates products for safety risks, determining whether they can withstand extensive testing for electrical safety, such as overheating and fire risk. Electric blankets that hold a UL certification have passed rigorous assessments to ensure they meet the necessary safety protocols.

Another notable certification is the Canadian Standards Association (CSA) certification, which serves a similar purpose as UL but in the Canadian market. CSA standards ensure that electric blankets are designed to minimize fire hazards and are tested for both performance and safety. Consumers should look for these certifications when choosing electric blankets, as they signify adherence to stringent safety guidelines and provide peace of mind regarding potential fire dangers.

There are also certifications from the International Electrotechnical Commission (IEC), which focuses on international standards for electrical technologies. IEC certifications ensure that electric blankets meet global safety requirements and reduce risks associated with electrical failures. This is especially relevant for businesses that import or export electric blankets, as compliance with international safety standards is essential for broad market acceptance.

In addition to these certifications, businesses that sell electric blankets must ensure they are aware of local regulations and standards that apply to commercial usage. This mindfulness in selecting electric blankets not only promotes safety but also enhances customer trust and satisfaction. By prioritizing certified products, both consumers and businesses can significantly mitigate the risks of fire hazards associated with electric blankets.

Best Practices for Safe Electric Blanket Use in Commercial Settings

Ensuring the safe use of electric blankets in commercial settings is paramount to minimizing fire hazards and protecting users. Proper installation is the first step in guaranteeing safety. Electric blankets should be installed according to the manufacturer’s guidelines, ensuring that all connections are secure and compliant with local electrical codes. It is advisable to have qualified personnel conduct the installation to mitigate risks associated with improper wiring or incorrect settings.

Regular maintenance plays a critical role in sustaining the performance and safety of electric blankets. Establishing a routine maintenance schedule is essential. Inspections should focus on identifying any signs of wear, frayed cables, or malfunctioning controls. Any damaged electric blankets should be removed from use immediately and repaired or replaced as needed. Regular checks ensure that blankets are functioning correctly and safely, preventing potential fire hazards associated with defective wiring or overheating.

User training is equally important for the safe utilization of electric blankets in a commercial environment. Employees should be educated on the correct usage, including how to operate the blankets safely and what to do in case of emergencies. It is beneficial to conduct training sessions that cover essential safety protocols and the identification of potential hazards. Providing clear instructions for usage could significantly reduce the risk of accidents or injuries.

Conducting safety inspections is another critical facet of ensuring electric blanket safety. Establish a checklist that includes evaluating the condition of each blanket, ensuring electrical connections are secure, and verifying that blankets are being used in accordance with safety guidelines. A thorough inspection routine will reinforce adherence to fire safety standards while promoting overall awareness of potential electric blanket fire hazards.

The Role of Manufacturers in Ensuring Safety

Manufacturers of electric blankets play a crucial role in ensuring the safety and reliability of their products, addressing the inherent fire hazards associated with their use. Their responsibilities extend beyond mere compliance; manufacturers are tasked with implementing comprehensive safety measures that align with established standards and certifications. This proactive approach begins with an understanding of the specific safety requirements outlined by regulatory bodies, enabling manufacturers to design products that mitigate risks effectively.

One key aspect of a manufacturer’s responsibility is conducting rigorous testing of electric blankets before they reach the market. This testing process typically includes assessing the blankets’ electrical components, thermal performance, and structural integrity under various conditions. By adhering to testing protocols, manufacturers can identify potential defects and ensure that their products meet safety standards, thereby minimizing the risk of fire or injury associated with faulty products. Additionally, manufacturers must stay informed about advancements in technology and materials, allowing them to incorporate safety-enhancing features into their designs.

Providing clear and comprehensive user instructions is another essential responsibility of manufacturers. Instructions should include guidelines on proper use, maintenance, and care for electric blankets, as well as warnings about potential hazards. By empowering consumers with the knowledge to use products safely, manufacturers contribute significantly to fire prevention. Furthermore, transparency regarding product testing results and compliance with safety standards can enhance consumer trust. When consumers are aware that a product has undergone rigorous safety evaluations, they are more likely to have confidence in its reliability.

In summary, manufacturers are integral to ensuring the safety of electric blankets. Through adherence to safety standards, thorough testing, clear user instructions, and transparency, manufacturers can significantly reduce fire hazards and foster consumer trust. Their commitment to these responsibilities not only enhances safety but also reinforces the overall integrity of the electric blanket industry.

Case Studies on Electric Blanket Safety in Commercial Use

The implementation of electric blankets in commercial settings has seen a variety of applications, from hospitality to healthcare. One notable case study is that of a large hotel chain, which integrated electric blankets into their bedding arrangements to enhance guest comfort during winter months. The hotel undertook rigorous safety measures by selecting blankets that adhered strictly to safety certifications, such as UL and CE markings. Staff was educated about safe usage, which included ensuring that blankets were unplugged after use and regularly inspected for wear and tear. As a result, the hotel reported positive guest feedback and no incidents related to electrical hazards since the introduction of the blankets.

Conversely, a case involving a care facility for seniors highlights the importance of stringent safety protocols. The facility invested in quality electric blankets but overlooked proper staff training regarding their maintenance and inspection. Unfortunately, this led to an incident where a malfunctioning blanket caused minor burns to a resident. Following this incident, the facility re-evaluated its procedures, implementing a comprehensive training program for staff and enhancing their regular inspection routines. They have since adopted blankets with more advanced safety features, such as automatic shut-off mechanisms, significantly reducing the risk of further incidents.

These case studies underline that while electric blankets can greatly enhance comfort in commercial settings, they must be used judiciously with a strong emphasis on safety. The lessons learned from both successful implementations and unfortunate incidents emphasize the necessity of compliance with safety standards and regular staff training. In the evolving landscape of commercial electric blanket use, the commitment to safety remains paramount in preventing hazards while maximizing the benefits of these devices.

Conclusion

In light of the significant insights shared regarding electric blanket fire hazards, it is imperative to emphasize the necessity of compliance with established standards and regulations. The discussion has highlighted how adherence to safety protocols can mitigatively influence the risks associated with electric blankets, particularly in commercial settings. Compliance with industry standards such as UL (Underwriters Laboratories) certification ensures that electric blankets are subjected to rigorous testing, confirming their safety for consumer and business use.

Manufacturers play a critical role in this landscape by committing to high-quality designs that prioritize safety. They must embrace responsibility through ongoing testing and improvement of their products, ensuring that electric blankets maintain safety features that prevent overheating and reduce fire hazards. This commitment not only fosters trust among consumers but also aligns with regulatory expectations that demand reliable and safe products on the market.

Moreover, best practices for utilizing electric blankets cannot be understated. Consumers and businesses alike should educate themselves on the proper usage, maintenance, and storage of these heating devices. Regularly inspecting electric blankets for any signs of wear and adhering to manufacturer guidelines can significantly decrease the likelihood of accidents. Awareness and vigilance are key components in establishing a culture of safety surrounding electric blanket use.

Ultimately, prioritizing safety in the use of electric blankets is a shared responsibility. It falls to manufacturers to provide safe products, regulators to enforce guidelines, and consumers to use the blankets responsibly. By fostering a collective commitment to these principles, we can effectively minimize the fire hazards associated with electric blankets, ensuring a safe and comfortable experience for everyone involved.